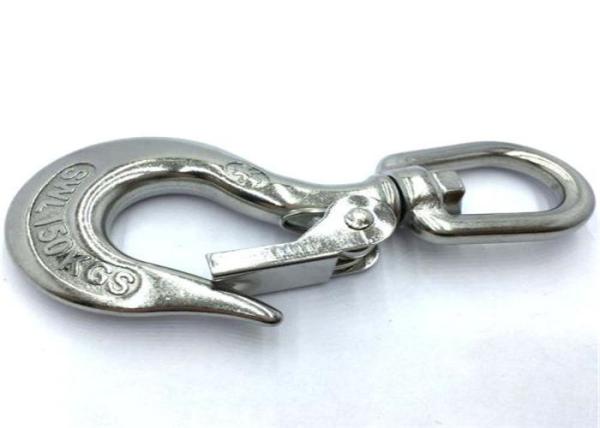

SS304 Stainless Steel Casting Investment Castings Drop Hanger Part

Custom Castings

Product Description and Process

Production process: Silica Sol lost wax investment casting process

Machining process: CNC machine, machining center, lathe, mill

machine, drill machine, etc.

Product Material and Uses

Normally produce with ASTM A743/A743M Grade CF8, CF8M, CF3, CF3M,

ZG0Cr18Ni10, ZG0Cr18Ni9, ZG0Cr18Ni9Ti, ZG0Cr18Ni12Mo2Ti,

ZG1Cr18Ni12Mo2Ti, etc.

POPULAR STAINLESS STEEL GRADES: SS 304 | SS 410 | SS 316 | 17-4

We has experience pouring a wide variety of stainless steel alloy

casts. We cast stainless steel from miniature to 50 pounds.

The most common alloys we have poured are listed below. We are also

capable of pouring other air melt alloys upon your request.

Specific material chemistry and mechanical specifications will be

provided to you if needed. For your Stainless Steel Castings needs,

we can help you out.

Commonly Cast Stainless Steel Alloys:

Stainless Steel 304(1.4308)

This is the most common stainless steel and is applied in different

applications. It consists of at least 18% chromium and 8% nickel

and has no magnetic properties within its austenitic structure.

Stainless Steel 304L(1.4309)

Corresponds to stainless steel 304. The ‘L’ stands for ‘low

carbon’, so this stainless steel has a lower carbon amount to

increase weldability and to limit the corrosion sensitivity after

welding.

Stainless Steel 316(1.4408)

A better, but more expensive type of corrosion resistant steel is

stainless steel 316. This alloy contains at least 16% chromium, 10%

nickel and 2% molybdenum. Because of the addition of molybdenum,

this stainless steel type is better defended against salt corrosion

and acids, and is often applied in chemical industries.

Stainless Steel 316L(1.4409)

Comparable to stainless steel 316 but with a lower carbon level to

increase weldability of the stainless steel.

17-4 PH(1.4549)

A high quality stainless steel which is regularly used in the

aircraft industry. It is characterized by a high tensile strength,

hardness, toughness and is also corrosion resistant.

Stainless Steel - Grade 304 (UNS S30400)

Chemical Formula

Fe, <0.08% C, 17.5-20% Cr, 8-11% Ni, <2% Mn, <1% Si,

<0.045% P, <0.03%

Background

Grade 304 is the standard "18/8" stainless; it is the most

versatile and most widely used stainless steel, available in a

wider range of products, forms and finishes than any other. It has

excellent forming and welding characteristics. The balanced

austenitic structure of Grade 304 enables it to be severely deep

drawn without intermediate annealing, which has made this grade

dominant in the manufacture of drawn stainless parts such as sinks,

hollow-ware and saucepans. For these applications it is common to

use special "304DDQ" (Deep Drawing Quality) variants. Grade 304 is

readily brake or roll formed into a variety of components for

applications in the industrial, architectural, and transportation

fields. Grade 304 also has outstanding welding characteristics.

Post-weld annealing is not required when welding thin sections.

Grade 304L, the low carbon version of 304, does not require

post-weld annealing and so is extensively used in heavy gauge

components (over about 6mm). Grade 304H with its higher carbon

content finds application at elevated temperatures. The austenitic

structure also gives these grades excellent toughness, even down to

cryogenic temperatures.

Key Properties

These properties are specified for flat rolled product (plate,

sheet and coil) in ASTM A240/A240M. Similar but not necessarily

identical properties are specified for other products such as pipe

and bar in their respective specifications.

Composition

Typical compositional ranges for grade 304 stainless steels are

given in table 1.

Table 1. Composition ranges for 304 grade stainless steel

| Grade | | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 304 | min.

max. | -

0.08 | -

2.0 | -

0.75 | -

0.045 | -

0.030 | 18.0

20.0 | - | 8.0

10.5 | -

0.10 |

| 304L | min.

max. | -

0.030 | -

2.0 | -

0.75 | -

0.045 | -

0.030 | 18.0

20.0 | - | 8.0

12.0 | -

0.10 |

| 304H | min.

max. | 0.04

0.10 | -

2.0 | -

0.75 | -0.045 | -

0.030 | 18.0

20.0 | - | 8.0

10.5 | - |

Mechanical Properties

Typical mechanical properties for grade 304 stainless steels are

given in table 2.

Table 2. Mechanical properties of 304 grade stainless steel

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50 mm) min | Hardness |

| Rockwell B (HR B) max | Brinell (HB) max |

| 304 | 515 | 205 | 40 | 92 | 201 |

| 304L | 485 | 170 | 40 | 92 | 201 |

| 304H | 515 | 205 | 40 | 92 | 201 |

304H also has a requirement for a grain size of ASTM No 7 or

coarser.

Physical Properties

Typical physical properties for annealed grade 304 stainless steels

are given in table 3.

Table 3. Physical properties of 304 grade stainless steel in the

annealed condition

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100 °C (J/kg.K) | Electrical Resistivity (nΩ.m) |

| 0-100 °C | 0-315 °C | 0-538 °C | at 100 °C | at 500 °C |

| 304/L/H | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

Grade Specification Comparison

Approximate grade comparisons for 304 stainless steels are given in

table 4.

Table 4. Grade specifications for 304 grade stainless steel

| Grade | UNS No | Old British | Euro norm | Swedish SS | Japanese JIS |

| BS | En | No | Name |

| 304 | S30400 | 304S31 | 58E | 1.4301 | X5CrNi18-10 | 2332 | SUS 304 |

| 304L | S30403 | 304S11 | - | 1.4306 | X2CrNi19-11 | 2352 | SUS 304L |

| 304H | S30409 | 304S51 | - | 1.4948 | X6CrNi18-11 | - | - |

These comparisons are approximate only. The list is intended as a

comparison of functionally similar materials not as a schedule of

contractual equivalents. If exact equivalents are needed original

specifications must be consulted.

Corrosion Resistance

Excellent in a wide range of atmospheric environments and many

corrosive media. Subject to pitting and crevice corrosion in warm

chloride environments, and to stress corrosion cracking above about

60 °C. Considered resistant to potable water with up to about 200

mg/L chlorides at ambient temperatures, reducing to about 150 mg/L

at 60 °C.

Applications

Typical applications include:

- Food processing equipment, particularly in beer brewing, milk

processing & wine making.

- Kitchen benches, sinks, troughs, equipment and appliances

- Architectural panelling, railings & trim

- Chemical containers, including for transport

- Heat Exchangers

- Woven or welded screens for mining, quarrying & water filtration

- Threaded fasteners

- Springs

The latest Stainless Steel Material Grade Standard Contrast

| China GB | Japan JIS | America | Korea KS | EU BS EN | Australia AS |

| Old Grade | New Grade | ASTM | UNS |

| austenitic stainless steel |

| 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 201-2 |

| 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - |

| 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 301 |

| 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 304 |

| 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 304L |

| 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | 304N1 |

| 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | 304N2 |

| 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | - | 304LN |

| 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | 305 |

| 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | 309S |

| 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | 310S |

| 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 316 |

| 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | - | 1.4571 | 316Ti |

| 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 316L |

| 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | - | 316N |

| 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | 316LN |

| 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | 316J1 |

| 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - |

| 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | - | 317 |

| 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | 317L |

| 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 321 |

| 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.455 | 347 |

| austenitic -ferrite stainless steel (duplex stainless steel) |

| 0Cr26Ni5Mo2 | - | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | 329J1 |

| 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | - | S31803 | STS329J3L | 1.4462 | 329J3L |

| ferrite stainless steel |

| 0Cr13Al | 06Cr13Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 405 |

| - | 022Cr11Ti | SUS409 | 409 | S40900 | STS409 | 1.4512 | 409L |

| 00Cr12 | 022Cr12 | SUS410L | - | - | STS410L | - | 410L |

| 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 430 |

| 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | 434 |

| - | 022Cr18NbTi | - | - | S43940 | - | 1.4509 | 439 |

| 00Cr18mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | 444 |

| martensitic stainless steel |

| 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | - | 403 |

| 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 410 |

| 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 420 |

| 3Cr13 | 30Cr13 | SUS420J2 | - | - | STS420J2 | 1.4028 | 420J2 |

| 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | - | 440A |

Different Types of Stainless Steel

| Material No. | Symbol | Similar to | Heat treatment | Proof stress Rp0,2 | Tensile strength (N/mm²) | Elongation (%) | Hardness |

| 1.4008 | GX7CrNiMo12-1 | AISI 410 | Refining | ≥ 440 | 590-790 | ≈ 15 | ≥ 90 HRb |

| 1.4027 | GX20Cr14 | - | Refining | ≥ 400 | 590-790 | ≈ 15 | 18-50 HRc |

| 1.4036 | GX46Cr13 | - | Refining | - | 750-900 | - | 15-53 HRc |

| 1.4059 | GX22CrNi17 | - | Refining | 600- 750 | 800-950 | ≈ 8 | 22-50 HRc |

| 1.4162 | X2CrMnNiN21-5-1 | LDX2101 ® | Solution annealing + quench hardening | - | - | - | - |

| 1.4308 | GX5CrNi19-10 | AISI 304 / CF8 | Solution annealing + quench hardening | > 175 | > 440 | > 30 | 75-90 HRb |

| 1.4309 | GX2CrNi19-11 | AISI 304L / CF3 | Casting condition | > 210 | 440-460 | > 30 | 70-80 HRb |

| 1.4317 | GX4CrNi13-4 | - | Refining | > 650 | 800-1000 | > 15 | 22-30 HRc |

| 1.4408 | GX5CrNiMi19-11-2 | AISI 316 / CF8M | Solution annealing + quench hardening | > 200 | > 450 | > 20 | 75-90 HRb |

| 1.4409 | GX2CrNiMi19-11-2 | AISI 316L / CF3M | Solution annealing + quench hardening | > 200 | > 450 | > 20 | 75-90 HRb |

| 1.4468 | GX2CrNiMoN25-6-3 | - | Casting condition | - | > 650 | > 22 | > 92 HRb |

| 1.4470 | GX2CrNiMoN22-5-3 | - | Normal annealing | > 450 | 680-880 | > 30 | > 93 HRb |

| 1.4827 | GX8CrNiNb19-10 | - | Solution annealing + quench hardening | > 175 | > 440 | > 20 | 75-95 HRb |

| 1.4815 | GX8CrNiNb19-10 | - | - | - | - | - | - |